Laser Engraver

SUPERSPEED-660

The maximum printable area for this laser engraver is 800 x 450 mm, and we typically use 3mm material.

SUPERSPEED-660 Power & Speed Settings

| # | Layer | Colour | Plotting | Power | Speed | PPI |

| 1 | 0 (LAYOUT) | White/Black | Skip | 0% | 100% | 500 |

| 2 | 3MM CUTTING | Red | Vector | 50% | 5% | 500 |

| 3 | OUTLINE – SLOW | Green | Vector | 5% | 5% | 500 |

| 4 | OUTLINE – FAST | Yellow | Vector | 10% | 10% | 500 |

| 5 | RASTER – LIGHT | Blue | Raster | 10% | 80% | 500 |

| 6 | RASTER – DARK | Magenta | Raster | 20% | 80% | 500 |

| 7 | 6MM CUTTING | Cyan | Vector | 60% | 3% | 500 |

| 8 | SECOND CUT | Orange | Vector | 5% | 5% | 500 |

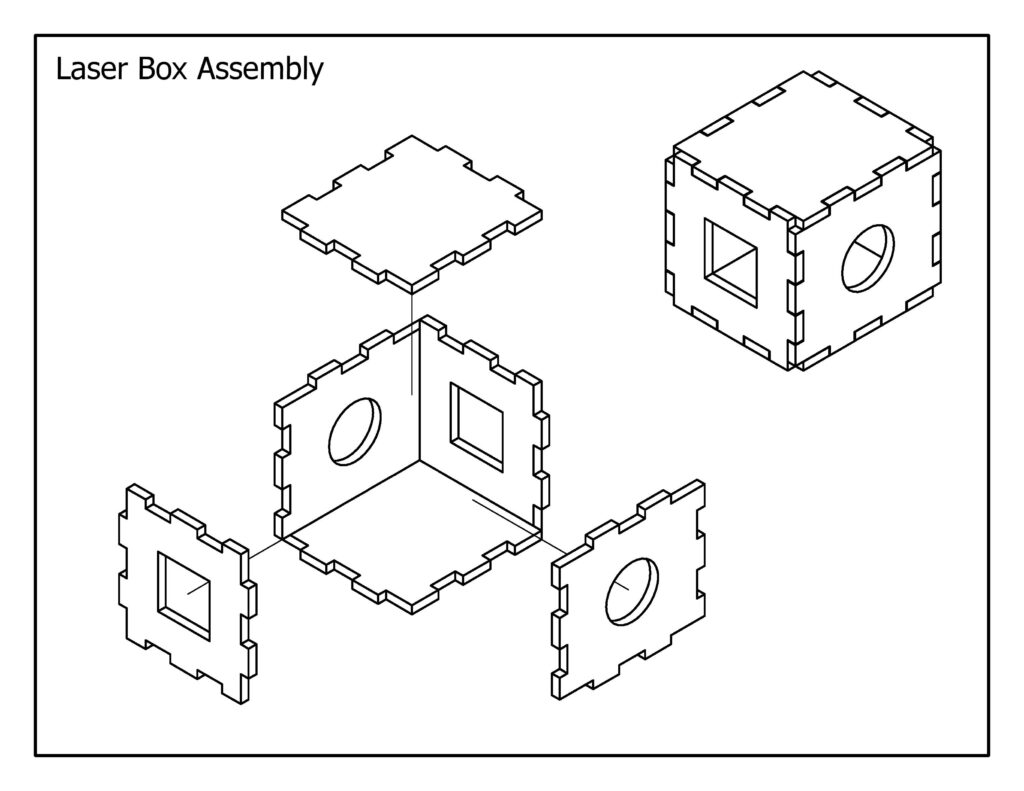

Sizing Tabs for Joints

Use a 0.5mm difference in size between the male and female sides of the joint.

The male side should be 0.5mm larger, but still centered with the female tab.

Note: These sizes only work with both 3mm and 6mm plywood.